Embracing Sustainability with HVO100

Introduction

EcoDataCenter addresses challenges and embraces sustainability with Hydrotreated Vegetable Oil (HVO100).

EcoDataCenter, founded in 2014, operates in the Nordic region, providing sustainable and reliable data center services.

The company is a pioneer in combining innovative technology with sustainability, always striving to push the boundaries of what is possible.

Building from the Ground Up

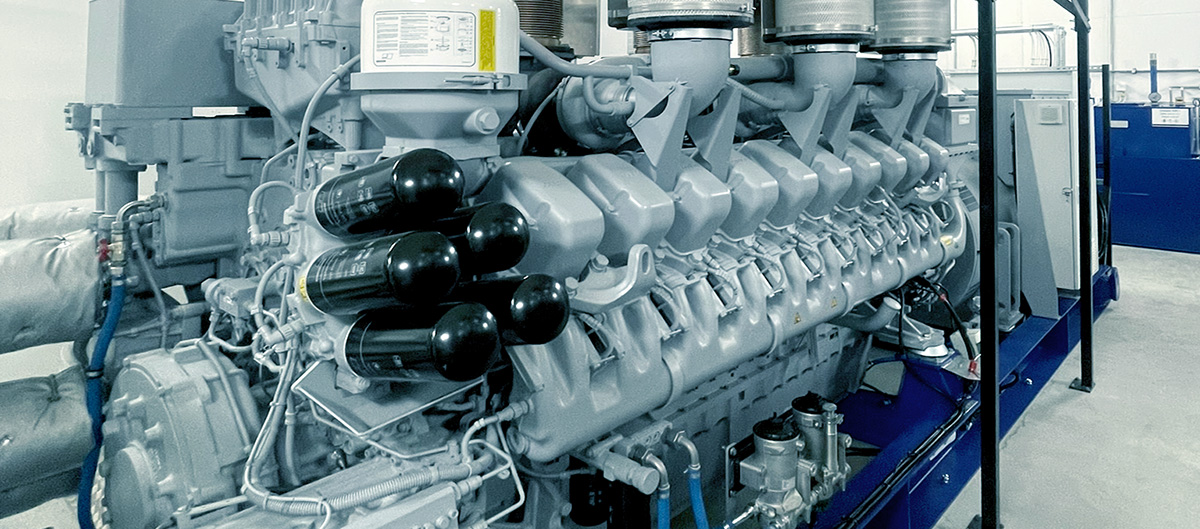

EcoDataCenter, in collaboration with BOS Power, Elektromatik, and Rolls-Royce Power Systems, has developed a customized backup power solution that aligns with the company’s sustainability requirements.

Together, they designed a redundancy structure that enhances both reliability and sustainability without compromising technical requirements.

According to Mikael Svanfeldt, CTO of EcoDataCenter, this also laid the foundation for the next project: “Since we have engines supplied by Elektromatik/BOS Power, it was natural for us to involve them in the HVO100 discussion, which included in-depth technical analysis with documented test runs and guarantees for the same or better performance of our systems. We were met with a highly professional response, addressing all our questions with formal documentation for product guarantees and performance.”

Finding A Greener Alternative To Diesel

Industry Leader

EcoDataCenter has long been a leader in sustainability within the industry, but they wanted to further reduce their carbon footprint, specifically related to the use of diesel in backup power systems.

Finding a more sustainable alternative to fossil diesel was crucial to maintaining the company’s environmental standards.

Svanfeldt explains that the decision to switch to HVO was another way to demonstrate that there are solutions that reduce emissions. “Since diesel is our biggest source of carbon emissions when accounting for Scope 1+2, we had to find other solutions. Moving away from fossil fuels was one of the cornerstones for success, which is why it has been our main focus recently.”

Jess Thorsen, CTO at BOS Power, elaborates: “The primary goal was to minimize their environmental impact while maintaining the stability and continuity of the backup power supply and reducing the use of fossil fuels.”

First steps

The first step was to consult with mtu and Elektromatik/BOS Power about the best-suited alternative fuels, says Svanfeldt. Jess Thorsen explains how EcoDataCenter sought an alternative to fossil fuel that aligned with the company’s policy and the goal of minimizing the environmental impact.

“Due to insufficient field tests and existing installed base, there was a need for a supplier and manufacturer for both the fuel itself and the operation of the engines for which the fuel was intended,” says Thorsen.

BOS Power worked with Rolls-Royce Power Systems (RRPS) to gain detailed knowledge of mtu genset performance with HVO and about Rolls-Royce Power Systems’ strategic partnership with Neste.

“RRPS and Elektromatik/BOS Power worked according to EcoDataCenter’s decision process, involving their own and Neste’s experts with local presence,” says Michael Stipa, Vice President of Business Development and Product Management, Stationary Power Solutions at Rolls-Royce Power Systems.

Considerations

When EcoDataCenter considered switching to HVO100 fuel, the first obstacle was obtaining approval from the engine manufacturers to ensure operational functionality, engine durability, and serviceability, and to understand what would change. What impact would this have on daily operations in both the short and long term?

Secondly, securing continuous fuel supply (HVO100) and sufficient volumes to support the need over an extended period was prioritized.

Thirdly, the requirement for cleaning and the ability to mix fuels (HVO100 and fossil diesel) was relevant during the transition. This is because the engines cannot be completely cleaned, and the fuel systems (including storage tanks) currently in use cannot be replaced and/or cleaned completely as they are part of an operational data center. However, HVO is fully blendable with diesel in any proportion without special procedures, allowing a smooth transition to HVO.

“Given the well-documented performance from mtu (engine manufacturer) and the close collaboration between Neste and mtu, it was decided that a fuel switch could be made with full confidence that operations would not be compromised,” says Thorsen.

“We verified the proposed alternatives through independent experts and then decided to choose HVO as an alternative,” says Mikael Svanfeldt. “We also had to validate the fuel supply chain given the local conditions. mtu supported here by informing us of which fuel producers and suppliers we could use. We currently have HVO100 in our fuel tanks with the ambition to continue using it as the primary fuel for all our expansions.”

Solution Description

EcoDataCenter collaborated with Elektromatik/BOS Power and involved Neste and Rolls-Royce Power Systems to explore the use of Hydrogenated Vegetable Oil (HVO100).

HVO100, offered by Neste, is a renewable diesel made from renewable raw materials.

“The data center’s combustion engines, which are on standby in emergencies, operate more efficiently and sustainably with renewable diesel, also known as HVO100. Neste’s HVO100, Neste MY Renewable Diesel™, is made from 100 % renewable raw materials and is a ‘drop-in fuel’ that can be used directly to switch from fossil diesel to renewable fuel – it’s just a matter of decision,” says Mats Hultman, Head of OEM Partnerships at Neste.

EcoDataCenter was able to reduce greenhouse gas emissions without investing in new equipment. Rolls-Royce Power Systems played a crucial role by ensuring that their mtu genset engines were fully compatible with HVO100, requiring no modifications and maintaining performance, warranty, and service intervals.

By using HV100 (Neste MY Renewable Diesel), they could reduce their greenhouse gas emissions by up to 90 %* when comparing the emissions over the fuel’s lifecycle with fossil diesel.

*The reduction in greenhouse gas emissions varies depending on the region-specific legislation that provides the methodology for the calculations (e.g., EU RED II 2018/2001/EU for Europe and US California LCFS for the USA), and the raw material mix used to produce the product for each market.

Benefits & Advantages

EcoDataCenter demonstrated to the industry that there are indeed solutions available to reduce emissions without compromising operational performance.

The site-specific mtu genset at EcoDataCenter will have the same load response, output, and durability

The key differentiation factors for gensets with HVO are:

- Material compatibility: No impact on material compatibility.

- Engine power: Comparable engine power.

- Time between overhaul: TBO and maintenance schedules remain the same.

- Engine adaptation: No hardware or software adaptations required for the engine.

- Load acceptance: Load acceptance behavior unchanged.

- Consumption: Similar fuel consumption.

- Standard warranty: Warranty period remains unchanged.

- Local emissions: 40–80 % fewer particles (mg/m³), up to 8 % less nitrogen oxides (ppm NOx).

The transition to HVO100 provided several benefits:

- Environmental Impact: Significant reduction in local emissions, including particles and nitrogen oxides, fully aligned with EcoDataCenter’s sustainability goals.

- Operational Efficiency: Maintaining engine performance and reliability ensured no compromise in uptime, a critical factor for data center customers.

- Scalability and Futureproofing: The flexibility of HVO100 and its compatibility with existing infrastructure make it a sustainable choice that can scale with EcoDataCenter’s growth and future plans.

- Reduced Emissions – Increased Lifespan: Extending the life and relevance of existing gensets and engines minimizes the need for energy to manufacture new engines, thus reducing emissions by reusing already utilized waste for food production.

"The fuel switch has had a significant impact on reducing our co₂ emissions. The cost of the fuel is slightly higher compared to fossil diesel, but fossil fuels must be phased out. For those concerned about storage in cold climates over several years, the cold Swedish winters are not an issue.

A thorough preparatory work with good documentation, where questions were continuously answered and results from tests in laboratories were presented. Even though it has no direct commercial impact on already installed units for mtu or BOS Power/ Elektromatik, they understood that this was a key point for us as a customer, and they supported us throughout the process of gathering information and making decisions.”

“HVO perfectly meets the needs of data center operators with optimized sustainability, cost-efficiency, and emission regulations.”

“The most important lesson from this collaborative project has been that we, together as strategic partners, can help our customers optimize their backup energy infrastructure and actively support them in transitioning to renewable diesel. It is crucial for data centers to serve their customers, such as critical infrastructure operations like hospitals, without interruption or compromise in performance or sustainability.”

“By using HVO100, EcoDataCenter extends the lifespan of the combustion engines (Internal Combustion Engines), allowing the already manufactured and operational units to continue being used without contributing to the negative environmental impact conventional diesel or GTL has.”

Partnerships

A significant part of the success is linked to the effective collaboration and EcoDataCenter’s vision for a greener future, a vision shared by the partners EcoDataCenter, Elektromatik/BOS Power, Neste, and Rolls-Royce Power Systems.

Each party contributed specific expertise, working together to develop a successful strategy. The project is a testament to the decarbonization of combustion engines through the successful collaboration between an engine manufacturer and a fuel producer, an example of sustainability in action. It exemplifies how strategic partnerships can lead to innovative solutions that benefit all involved stakeholders.

The project solution can be replicated for any industry that uses diesel-powered engines, whether for transportation with a high number of operating hours per day or emergency applications with limited operating hours per year. However, it cannot be just any engine, as only certain manufacturers can guarantee performance and functionality – such as mtu.

Conclusion

Contribution to a more sustainable future.

By showcasing the benefits of HVO100, this information aims to inspire other companies to consider how they too can contribute to a more sustainable future.

Do you want to take a step towards a more sustainable future? Or are you interested in exploring how HVO100 can help you reduce your emissions?

Resources: HVO: Good for mtu engines (mtu-solutions.com) More information on Neste’s renewable raw materials can be found in Neste’s annual report 2023 or at www.neste.com

Get in Touch

Do you want to learn more about our solutions or discuss how we can support your next project? Our team of experts is ready to answer your questions and explore opportunities together.- Let’s talk about your needs

- Share your ideas with us

- Start building a sustainable and reliable future today